Machine tools

Innovation in the DNA

Headquarter

The innovation in our DNA. This is the competitive attribute that has always characterized Sala srl, which is set in Collebeato (Brescia – ITALY), in the middle of one of the leading European industrial districts. The company was born in 1950 as a technical design studio established in Lumezzane (Brescia – ITALY) and, starting from the 80’s, has been well known in the world of precision turning providing unique and technologically advanced solutions.

History

1950 • THE BEGINNING

The technical design studio was established in Lumezzane, BS.

1960 • NEW CHALLANGE

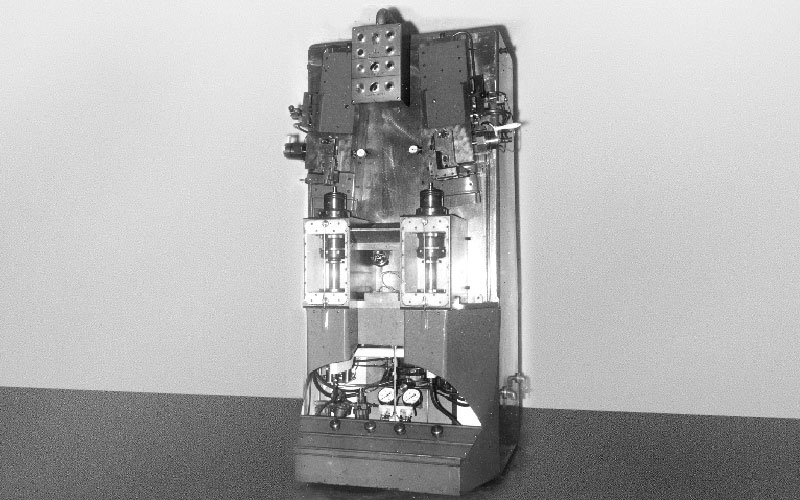

High-precision multispindle machines for gas valves industry.

1960 • NEW CHALLANGE

High-precision multispindle machines for gas valves industry.

1970 • INTERNATIONAL ACHIEVEMENT

The first diamond turning machine for balls for valve industry.

1991 • NEW LOCATION

Opening the new plant in Collebeato, Brescia (Italy).

1991 • NEW LOCATION

Opening the new plant in Collebeato, Brescia (Italy).

1994 • CNC NUMERICAL CONTROL

The first high-precision CNC vertical turning machine.

2011 • LINEA

The first linear multispindle turning machine for the complete processing of parts from bars, castings or forgings.

2011 • LINEA

The first linear multispindle turning machine for the complete processing of parts from bars, castings or forgings.

2018 • LINEA SPINDLE

The first linear multispindle built in series according to the Lean Manufacturing concepts.

How we work

In order to enhance its turning solutions among competition that the world of machine tools offers, Sala Srl relies on some key elements which, after 70 years of activity, would be impossible to disregard:

The Team

Over the years, we have brought together a group of people close-knit, motivated, and competent personnel who guarantee professionalism, efficiency and high quality of the product and the after-sales service.

Sala’s team keeps updating to be ready to satisfy the increasingly demanding market requirements and to follow the customer in all steps of their production.

R&D

Mechanical and electronic design of machinery is undertaken 100% by our technicians with the most advanced systems and design software. The goal is developing advanced solutions for both standard and special machines, on the basis of customer’s requirements.

Quality Control

In the machine tools field, a high quality level is due to:

The quality control department is equipped with all the tools necessary to check and guarantee the quality of machines tools.

Assembly Line and Delivery

A new area of the plant is used for the assembly and testing. Here, each machine tool is tested in all its functions and each piece produced by the new machine tool undergoes a strict quality check too.

The customer carries out a production test at the firm, where he also receives a first training that will be completed at the time of installation, with SALA® technician support.

After Sales Service

The path starts together with the customer at the time of drafting the project and is not interrupted by the sale. SALA®’s technicians are always at customer’s disposal: the customer can always count on SALA®’s after-sales service. In addition to telephone assistance and remote assistance, we offer PROGRAMMED MAINTENANCE SERVICES: through direct interventions, SALA® technicians carry out all checks and maintenance activities that the machine needs. The highest levels of machine efficiency are thus guaranteed over time.